by Soumyajit Admin

Share

The manufacturing industry plays a vital role in the global economy, producing everything from consumer goods to industrial equipment. However, it faces a myriad of challenges that can impact its efficiency, profitability, and sustainability. In the intricate landscape of the manufacturing industry, businesses often find themselves navigating a maze of challenges that demand seasoned guidance.

Before starting our article, we would like to draw your kind attention to Econstra. As a leading business consultant, Econstra takes center stage in providing invaluable insights to manufacturing enterprises grappling with issues ranging from global supply chain disruptions to technological advancements. Our role extends beyond mere consultation, as we actively collaborate with businesses to devise tailored strategies that foster resilience and growth.

With Econstra as your dedicated business consultant, you gain a strategic commitment to unraveling complexities, streamlining operations, and fortifying your position in the competitive market. Our expertise goes hand in hand with our commitment to delivering tangible results, making Econstra the go-to partner for manufacturing businesses striving for excellence in an ever-evolving landscape.

List Of Challenges in Manufacturing Business

Whether you are a seasoned manufacturer or considering entering this sector, understanding these challenges is crucial for success in the competitive world of manufacturing. So here is the list of some of the challenges of manufacturing business with solutions.

No. 1 Challenge In Manufacturing Business: Supply Chain Disruptions

Supply chains serve as the lifeblood of manufacturing enterprises, ensuring the smooth flow of raw materials, components, and goods throughout the production process. However, these intricate networks are susceptible to a wide array of disruptions that can inflict substantial harm. Whether triggered by unforeseen natural disasters, logistical challenges, or global crises such as the COVID-19 pandemic, these disruptions have the potential to wreak havoc on manufacturing operations.

They often result in delayed production timelines, elevated operational costs stemming from rush orders or alternative sourcing, and, perhaps most significantly, the disillusionment of customers who expected timely deliveries. In such a volatile landscape, proactive supply chain management and risk mitigation strategies are imperative for manufacturers to thrive.

Solution: To mitigate supply chain disruptions, businesses should diversify their suppliers, implement robust risk management strategies, and invest in technology to gain better visibility and control over their supply chains. This might include the use of data analytics and real-time tracking to detect and respond to disruptions swiftly.

No. 2 Challenge In Manufacturing Business: Technology Integration

In the contemporary, swiftly advancing technological landscape, manufacturers are compelled to stay abreast of cutting-edge innovations such as automation, artificial intelligence (AI), and the Internet of Things (IoT). These technological advancements offer the promise of enhanced efficiency, productivity, and competitiveness.

Nonetheless, the process of seamlessly integrating these new technologies into established manufacturing processes can pose significant hurdles. Such integration often demands substantial investments in terms of capital, time, and workforce upskilling. Navigating these challenges becomes imperative as manufacturers strive to remain agile and harness the transformative potential of these innovations in their pursuit of sustained success.

Solution: Manufacturers should develop a clear technology adoption strategy, including assessing the ROI of new technologies and providing training for employees. Collaborating with technology partners and staying informed about industry trends is also crucial.

No. 3 Challenge In Manufacturing Business: Regulatory Compliance

Manufacturers are obliged to adhere to a wide range of regulations encompassing environmental sustainability and safety measures. Staying in compliance with these multifaceted rules is a challenging and time-consuming endeavor. It demands a vigilant and comprehensive approach to ensure that production processes, materials, and products meet the stringent criteria set forth by regulatory authorities. This commitment to compliance is essential not only for legal reasons but also for upholding ethical and responsible business practices, fostering consumer trust, and safeguarding the environment and public safety.

Solution: Establish a compliance team or hire experts who can navigate the regulatory landscape. Invest in compliance management software to streamline processes and conduct regular audits to identify and rectify compliance gaps.

No. 4 Challenge In Manufacturing Business: Quality Control

Quality control in manufacturing is an unequivocal imperative, as the repercussions of subpar products can be detrimental to a brand’s standing and result in customer discontent. Ensuring the production of consistently high-quality items is an arduous task. It necessitates meticulous attention to detail, stringent adherence to specifications, and constant monitoring of various production stages.

Even minor deviations from established quality standards can have cascading consequences, potentially tarnishing a company’s image and eroding consumer trust. Hence, manufacturers must invest in rigorous quality control processes, leveraging advanced technologies and skilled personnel to uphold their commitment to delivering products that meet or exceed customer expectations, safeguarding their reputation in an ever-competitive market.

Solution: Implement Total Quality Management (TQM) principles, conduct rigorous inspections and testing, and empower employees to take ownership of quality control. Embrace Six Sigma and lean manufacturing techniques to continuously improve quality processes.

No. 5 Challenge In Manufacturing Business: Workforce Management

Achieving manufacturing success hinges on the presence of a proficient and driven workforce. Yet, the task of attracting and retaining skilled employees in today’s fiercely competitive job market presents a formidable challenge. Companies must offer enticing compensation packages, opportunities for skill development, and a positive work environment to entice top talent.

Additionally, fostering a culture of motivation and engagement is crucial to ensure employees remain committed and contribute effectively to the company’s goals, making the talent acquisition and retention process a pivotal aspect of manufacturing excellence.

Also read, Effective Solutions For Business Management Problems

Solution: Invest in employee training and development programs, offer competitive compensation packages, and create a positive work culture that fosters employee engagement and loyalty. Consider collaborating with local educational institutions to ensure a pipeline of skilled workers.

No. 6 Challenge In Manufacturing Business: Cost Management

Cost management is an ongoing struggle within the realm of manufacturing. The sector grapples with persistent challenges such as the volatility of raw material prices, escalating energy expenses, and intense competition, all of which can chip away at profit margins

. Manufacturers must employ meticulous cost-control strategies, from sourcing cost-effective materials to optimizing energy efficiency in production processes. Additionally, they must continuously innovate to enhance productivity and reduce waste. These efforts are essential to not only maintain competitiveness but also to safeguard profitability in an environment where cost fluctuations are a constant threat.

Solution: Employ cost-effective manufacturing processes, negotiate favorable supplier contracts, and implement energy-efficient technologies. Continuously monitor expenses and explore opportunities for cost reduction without compromising product quality.

No. 7 Challenge In Manufacturing Business: Sustainability

In today’s era, characterized by heightened environmental consciousness, sustainability transcends mere trendy jargon; it has evolved into a critical business imperative. Manufacturers are under mounting pressure to proactively curtail their environmental impact and embrace eco-conscious practices. This entails a paradigm shift towards greener processes, resource-efficient production methods, and the incorporation of renewable energy sources.

Meeting these demands not only aligns with ethical and environmental obligations but also resonates with consumers who increasingly favor eco-friendly brands. Hence, sustainability has become a pivotal aspect of manufacturing strategy, vital for long-term competitiveness and corporate responsibility.

Solution: Develop a sustainability strategy that includes reducing waste, conserving energy, and sourcing materials responsibly. Consider certifications like ISO 14001 for environmental management. Communicate your commitment to sustainability to customers, as it can be a selling point.

No. 8 Challenge In Manufacturing Business: Market Volatility

Manufacturers, like all businesses, are susceptible to market fluctuations, whether triggered by economic recessions or shifts in consumer preferences. Adapting to these dynamic conditions can be a formidable task. Economic downturns can disrupt supply chains, affect production volumes, and strain financial resources. Conversely, changing consumer demand necessitates swift adjustments in product offerings and production processes. To thrive amidst such volatility, manufacturers must remain agile and responsive. This may involve diversifying product lines, investing in research and development, and embracing technology to optimize operations. Flexibility and the ability to swiftly pivot are essential attributes for manufacturers navigating the ever-changing marketplace.

Solution: Diversify your product offerings to serve multiple markets and industries, allowing for greater resilience in the face of market volatility. Invest in market research to anticipate trends and pivot your strategies accordingly. Building strong relationships with customers and suppliers can also provide stability.

How EconStra Helps Manufacturing Businesses to Overcome the Challenges?

EconStra plays a crucial role in helping manufacturing businesses overcome these challenges through a range of services and expertise:

- Tailored Solutions: EconStra recognizes that every manufacturing business is unique, with its own set of challenges and opportunities. What sets EconStra apart is its ability to craft tailored solutions that precisely address the specific needs of each client. By conducting in-depth assessments and understanding the intricacies of a client’s operations, EconStra ensures that its strategies and recommendations are not one-size-fits-all but rather finely tuned to be relevant and effective. This client-centric approach fosters a sense of partnership, where EconStra works hand in hand with manufacturers to achieve their objectives.

- Industry Expertise: EconStra boasts a team of consultants who possess extensive and diverse experience within the manufacturing sector. This wealth of knowledge allows them to provide manufacturers with valuable insights, industry-specific best practices, and tried-and-tested methodologies. Whether it’s optimizing production processes, complying with industry regulations, or identifying emerging trends, EconStra’s consultants draw from their deep industry expertise to offer guidance that is not only relevant but also tailored to the nuances of manufacturing businesses.

- Data-Driven Decisions: In an era where data is king, EconStra empowers manufacturing businesses by harnessing the power of data analytics and financial analysis. They utilize sophisticated tools and methodologies to collect, analyze, and interpret data, enabling clients to make informed decisions. By adopting a data-driven approach, manufacturers can identify inefficiencies, track key performance indicators, and make strategic choices that optimize their operations and reduce costs. EconStra’s commitment to data-driven decision-making ensures that their clients remain competitive in an increasingly data-centric world.

- Comprehensive Services: EconStra takes a holistic approach to solving the multifaceted challenges faced by manufacturing businesses. They recognize that issues in one area can have ripple effects throughout an organization. As a result, EconStra manufacturing consultant offers a comprehensive suite of services that span the entire spectrum of manufacturing concerns. From supply chain management to sustainability initiatives, EconStra assists clients in developing a cohesive and integrated strategy. This approach ensures that manufacturers not only address immediate challenges but also create a resilient foundation for long-term success.

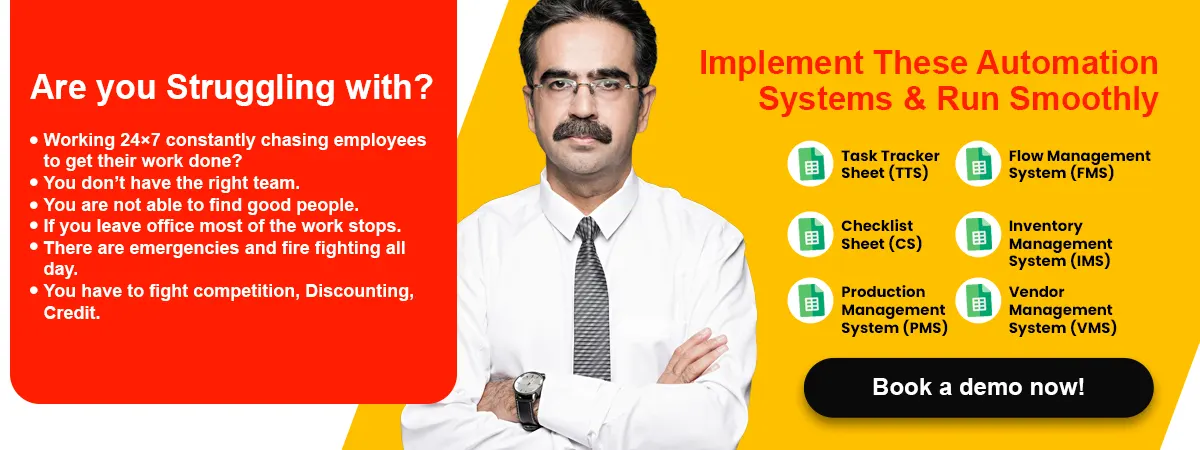

- Business Automation: EconStra stands out as a transformative partner for manufacturing businesses, offering unparalleled expertise as a business consultant combined with cutting-edge business automation solutions. In an industry rife with challenges, EconStra emerges as a beacon of innovation, helping manufacturing businesses navigate complexities and overcome obstacles. With a deep understanding of the manufacturing landscape, EconStra provides tailored consulting services to optimize operations, enhance efficiency, and drive sustainable growth. What sets EconStra apart is its unique blend of business consulting and automation solutions. By seamlessly integrating advanced technologies, EconStra empowers manufacturing businesses to streamline processes, reduce costs, and increase productivity. Whether it’s supply chain optimization, inventory management, or workflow automation, EconStra’s comprehensive approach ensures that every facet of the business is fine-tuned for success. In a rapidly evolving market, EconStra stands as a strategic ally, guiding manufacturing businesses toward a future of resilience and prosperity.

Also, check out our article Challenges & Benefits Of Business Process Automation

Conclusion On Challenges in Manufacturing Business

In the world of manufacturing, challenges are inevitable, but they are also opportunities for growth and improvement. By addressing supply chain disruptions, maintaining high-quality standards, managing costs, adapting to market volatility, embracing technology, ensuring compliance, addressing talent shortages, and prioritizing environmental sustainability, manufacturing businesses can navigate these challenges successfully.

Keep in mind that each challenge requires a tailored approach, and continuous innovation and adaptation are key to long-term success in the manufacturing industry. Stay proactive, stay agile, and your manufacturing business will thrive in the face of adversity.

STAY IN THE LOOP

Subscribe to our free newsletter.

In today’s competitive business landscape, companies are constantly seeking ways to reduce operational costs while maintaining or improving efficiency and customer satisfaction. Customer Relationship Management (CRM) systems have emerged as vital tools that enable businesses to achieve these goals. As a leading business consultancy, Econstra understands the importance of leveraging CRM technology to streamline operations, […]

Why Operational Costs Are Draining Your Profits? Operational costs are a critical aspect of running a successful business, but when not managed properly, they can drain your profits and stifle growth. In a competitive market, maintaining profitability requires keen oversight of expenses and strategic planning. Econstra, as a leading business consultancy, provides insights and strategies […]

In the rapidly advancing digital landscape, Artificial Intelligence (AI) tools have emerged as transformative assets for businesses. Their potential to enhance efficiency, streamline operations, and drive innovation makes them invaluable for business consultants and organizations worldwide. For business consultants in India, AI’s strategic application can be particularly advantageous in navigating a diverse and dynamic market. […]

In today’s competitive business landscape, marketing is more crucial than ever. Companies are constantly seeking innovative strategies to stay ahead of the curve. Yet, navigating the complexities of modern marketing requires more than just creativity; it demands expertise and strategic insight. This is where a Business Consultant can make a transformative impact. Business consultants offer […]